Tenka Orion technology redefines efficiency in photovoltaics. At its heart is the patented Nanotech coating, which enables an exceptionally high light yield thanks to millions of tiny prisms on the cell surface. Even weak or diffuse light is efficiently captured and converted into electricity - a clear advantage in changing weather conditions or limited light incidence.

Tenka Orion modules achieve measurably higher energy yields than conventional modules, particularly at off-peak times and when the sky is overcast. This technology maximizes the energy yield per square metre and makes roofs with limited space economically viable. At the same time, it reduces installation costs as fewer modules are required for the same output.

The combination of nanotechnology and high-quality cell architecture makes Tenka Orion an ideal solution for all areas of application - from private house roofs to large open-space systems. The optimized use of light noticeably extends the daily generation time, which creates significant additional yields, especially in the morning and evening hours.

Tenka Orion technology also impresses with long-term use: low degradation, high material quality and constant performance ensure long-term investment security. Tenka Orion modules thus set new standards for sustainable and powerful PV systems - both technically and economically.

In the photovoltaic industry, manufacturers generally offer one and the same module in different output levels, for example 465 watts, 460 watts, 455 watts or 450 watts. These gradations are due to the varying quality of the solar cells produced, which do not all have the same efficiency. Manufacturers test the cells individually after production and then sort them according to their performance. This means that only the most efficient cells are used for modules with the highest output, while less efficient cells are installed in modules with lower output levels.

At Tenka, we pursue an uncompromising quality strategy so that we have set ourselves the goal of offering only modules of the highest performance level. In production, our solar cells undergo a particularly strict selection process, which ensures that only cells with maximum efficiency are used for the European region. This enables us to offer only solar modules with the highest available output. This ensures maximum energy yield, optimum use of space and long-term profitability of every PV system.

Exclusive cooperation with Ariel RE/LLOYDS, a leading global provider of warranties for photovoltaic modules

Industry-leading warranty: Unique 30-year warranty on product and performance.

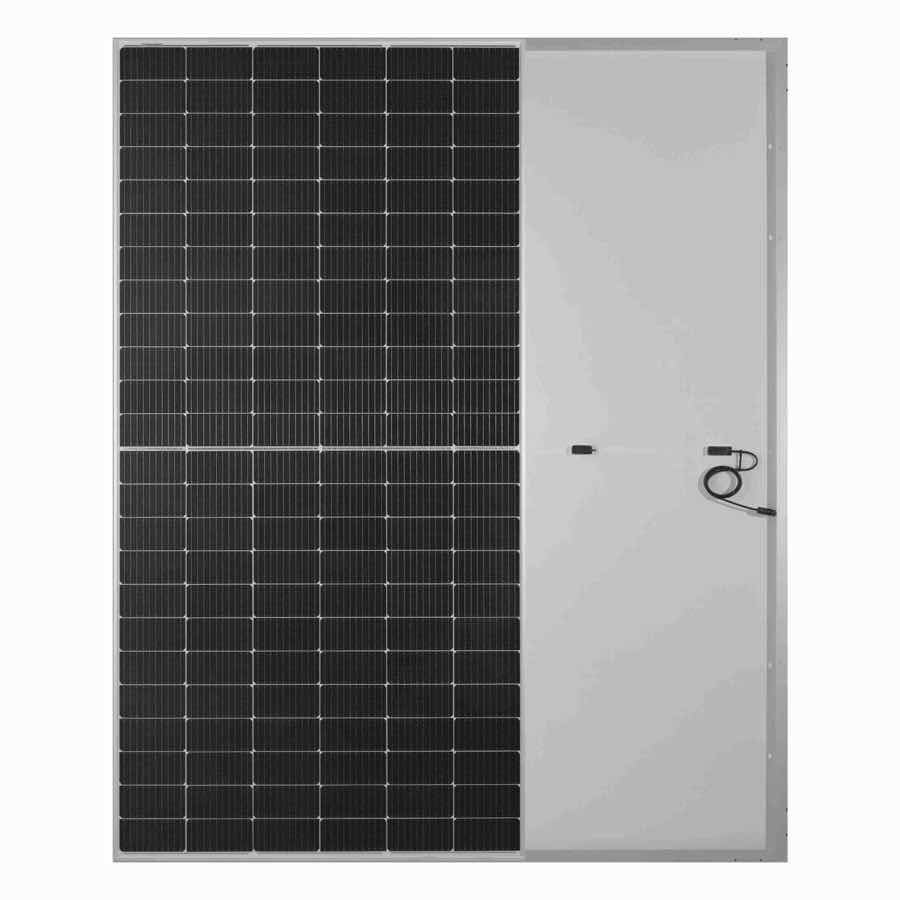

Monofacial solar modules only use the front side to generate electricity. The solar cells are only sensitive to light on one side and are embedded in a stable, opaque backsheet. This technology has been in use for decades and forms the basis for the majority of photovoltaic systems installed worldwide. Monofacial modules are robust, readily available and technically mature - a reliable standard in solar technology.

The modules consist of crystalline solar cells (usually PERC or TOPCon), which are protected by tempered glass on the front. The back is usually covered with plastic or glass, but is not translucent. This means that only the front can absorb sunlight and convert it into electrical energy. This clear focus on one active side considerably simplifies production, installation and system integration.

Monofacial modules impress with their cost efficiency and solid yields in a wide range of weather and site conditions. They are easier to install due to the one-sided use of light, do not require a special substructure and are therefore ideal for standard roof systems. The sophisticated technology offers many years of operational reliability and low degradation - a clear advantage when calculating PV investments.

Monofacial PV modules are mainly used on private house roofs, commercial roofs and industrial buildings. They are also a preferred choice for PV systems on carports or façades if there is no reflective surface. Thanks to their broad applicability, they are the first choice for PV projects where simple implementation, stability and cost control are paramount.

Bifacial solar modules convert sunlight into electrical energy on both the front and back. The solar cells are light-sensitive on both sides and embedded in transparent carrier materials such as glass. Thanks to this design, the modules also use reflected light from the ground or from the surroundings - a clear advantage over conventional monofacial modules.

Bifacial modules consist of double-sided active solar cells that are embedded between two panes of glass or in a glass-plastic composite. The rear side is translucent. Depending on the substrate - e.g. concrete, gravel or snow - reflective light can additionally activate the rear side and increase the total energy yield by up to 30 %.

The major advantage of bifacial modules is their higher specific energy yield, particularly with reflective substrates and optimum mounting angles. They offer improved area utilization, higher efficiencies and are particularly resistant to environmental influences. Even in diffuse lighting conditions or when the sun is low, they provide additional energy and thus increase overall efficiency.

Bifacial modules are preferably used in ground-mounted systems, on flat roofs with a reflective substrate or in agricultural PV systems. They also achieve good yields on carports or systems with an east-west orientation. They are particularly suitable where sufficient light is reflected from behind and the highest possible total output per area is to be achieved.

In photovoltaics, PERC and N-type TOPCon cells are two of the most important technologies currently dominating the market. Both variants are based on monocrystalline silicon, but differ in terms of their cell architecture, efficiency and durability. While PERC modules represent the established industry standard with a solid price-performance ratio, TOPCon technology relies on state-of-the-art cell contacts and optimized material properties to achieve maximum energy yield. Planners, installers and investors are therefore increasingly faced with the question of which solution makes the most economic and technical sense for which project environment.

The following comparison shows key differences between the two cell technologies - from efficiency and temperature behavior to long-term yields and degradation behavior. It is not just about theoretical parameters, but above all about the practical benefits in various application scenarios - for example, where space is limited, specific climatic conditions or budget constraints. Whether a large-scale solar park, industrial building or private home: choosing the right cell technology can determine the long-term economic success of a PV system. With an informed decision, performance and return on investment can be optimized in a targeted manner.

PERC stands for "Passivated Emitter and Rear Cell" and is a further development of classic monocrystalline solar cells. The special feature lies in the passivation of the rear side, which reflects unused sunlight and thus increases efficiency. Thanks to its proven design and mature production processes, PERC technology is one of the most widely used cell architectures in photovoltaics today.

In a PERC solar cell, the rear side is passivated with a dielectric layer that reduces recombination losses and reflects unused light back into the cell. At the same time, it improves electrical passivation, which means that fewer charge carriers are lost. Easy integration into existing production lines and moderate efficiencies of between 20% and 22% make PERC an efficient and economical standard solution.

The advantages of PERC technology lie primarily in its proven, stable performance, low manufacturing costs and broad market coverage. PERC modules offer a very good price-performance ratio, are suitable for large volume projects and are readily available worldwide. Thanks to their simple process control, they are extremely reliable and have been tried and tested over many years.

PERC modules are used in almost all areas of application - from residential buildings to commercial roof systems or large open-space parks. They are ideal when production costs are the focus and a stable yield with good efficiency is required. PERC is also often the first choice in markets with high price sensitivity.

The N-type TOPCon technology (Tunnel Oxide Passivated Contact) is a modern cell architecture based on n-type silicon. In contrast to PERC cells, TOPCon relies on an optimized back-surface structure with additional layers that enable more efficient power generation. TOPCon modules are technologically more sophisticated and achieve higher efficiencies.

At the center of TOPCon is an extremely thin tunnel oxide layer which, together with a polycrystalline silicon layer, establishes contact with the back surface. This combination reduces electrical resistance and improves charge carrier transport. The use of n-type wafers also significantly reduces light-induced degradation (LID).

TOPCon modules achieve efficiencies of over 24 % and are characterized by higher yields with less degradation. They work particularly well in low light and at high temperatures and retain their performance over their entire service life. The higher bifaciality of bifacial designs also contributes to the increase in yield.

TOPCon modules are preferably used where maximum output is required in a limited space - for example on industrial roofs or areas with high irradiation. They also demonstrate their strengths in particularly hot or poorly lit regions. TOPCon is a future-proof technology for premium projects or demanding customers.

There are no downloads available for this product.

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 670/675/680/685/690 Watt |

| efficiency: | 21,57 - 22,21 % |

| Cells: | 132 (6*22) |

| Bifacial: | No |

| Frame color: | silver |

| Front side: | 3.2 mm glass |

| Reverse side: | Foil white |

| Dimensions: | 2384*1303*35 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 670/675/680/685/690 Watt |

| efficiency: | 21,57 - 22,21 % |

| Cells: | 132 (6*22) |

| Bifacial: | No |

| Frame color: | silver |

| Front side: | 3.2 mm glass |

| Reverse side: | Foil white |

| Dimensions: | 2384*1303*35 mm |

| Guarantee: | 30 years |

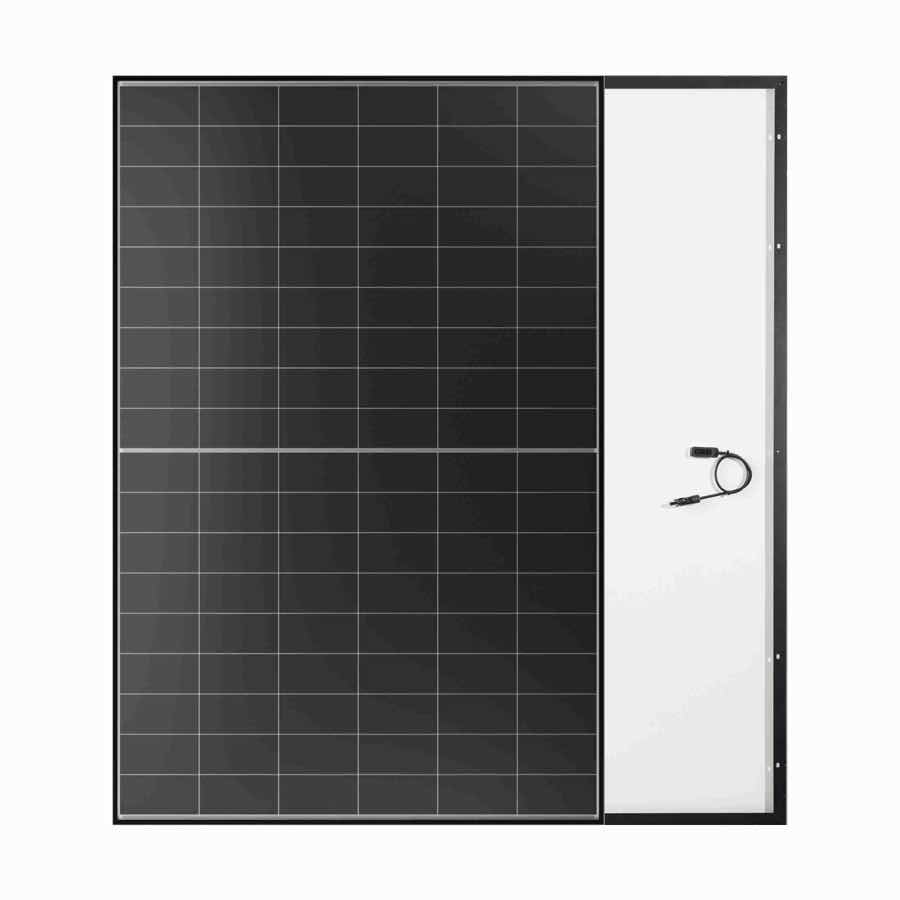

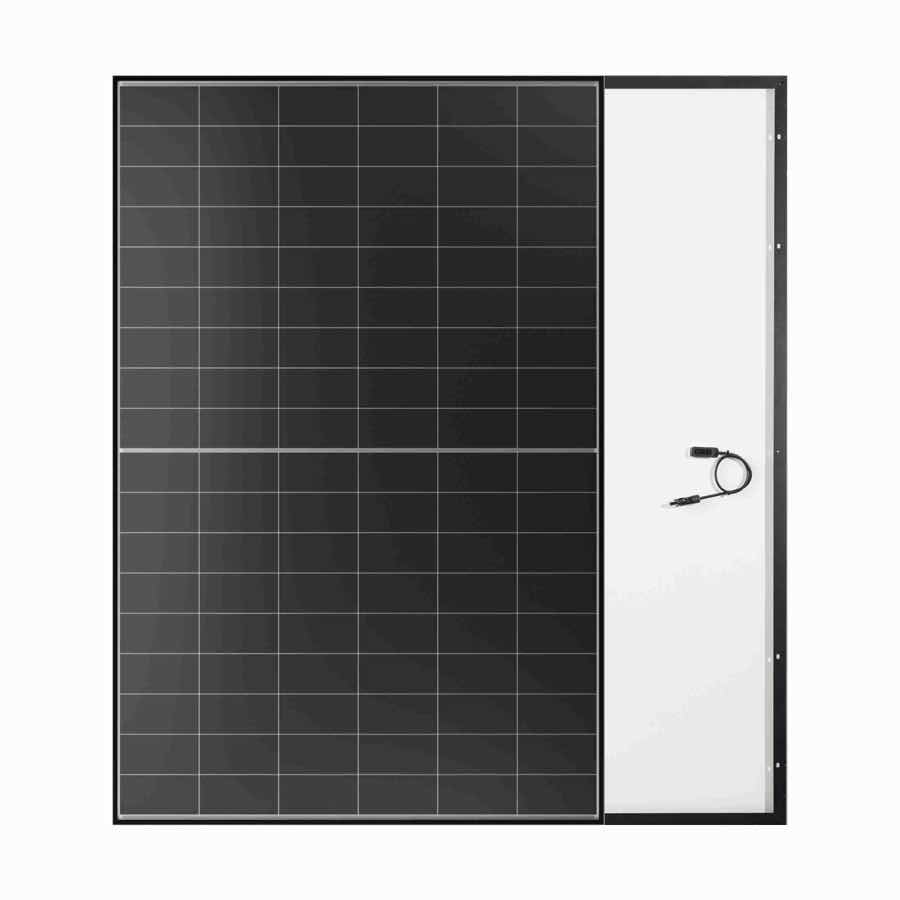

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 470/475/480/485 Watt |

| efficiency: | 23,02 - 23,76 % |

| Cells: | 108 (6*18) |

| Bifacial: | No |

| Frame color: | Black |

| Front side: | 3.2 mm glass |

| Reverse side: | Foil white |

| Dimensions: | 1800*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 470/475/480/485 Watt |

| efficiency: | 23,02 - 23,76 % |

| Cells: | 108 (6*18) |

| Bifacial: | No |

| Frame color: | Black |

| Front side: | 3.2 mm glass |

| Reverse side: | Foil white |

| Dimensions: | 1800*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | Bifacial, Glass/Glass, Back Contact, Full Black |

| Performance: | 480/485/490 watts |

| efficiency: | 23,5 - 24,0 % |

| Cells: | 108 (6*18) |

| Bifacial: | Yes, dual glass |

| Frame color: | Black |

| Front side: | 2 mm glass |

| Reverse side: | 2 mm glass |

| Dimensions: | 1800*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | Bifacial, Glass/Glass, Back Contact, Full Black |

| Performance: | 480/485/490 watts |

| efficiency: | 23,5 - 24,0 % |

| Cells: | 108 (6*18) |

| Bifacial: | Yes, dual glass |

| Frame color: | Black |

| Front side: | 2 mm glass |

| Reverse side: | 2 mm glass |

| Dimensions: | 1800*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 450/455/460/465 watts |

| efficiency: | 22,52 - 23,27 % |

| Cells: | 108 (6*18) |

| Bifacial: | No |

| Frame color: | Black |

| Front side: | 3.2 mm glass |

| Reverse side: | Foil white |

| Dimensions: | 1762*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 450/455/460/465 watts |

| efficiency: | 22,52 - 23,27 % |

| Cells: | 108 (6*18) |

| Bifacial: | No |

| Frame color: | Black |

| Front side: | 3.2 mm glass |

| Reverse side: | Foil white |

| Dimensions: | 1762*1134*30 mm |

| Guarantee: | 30 years |

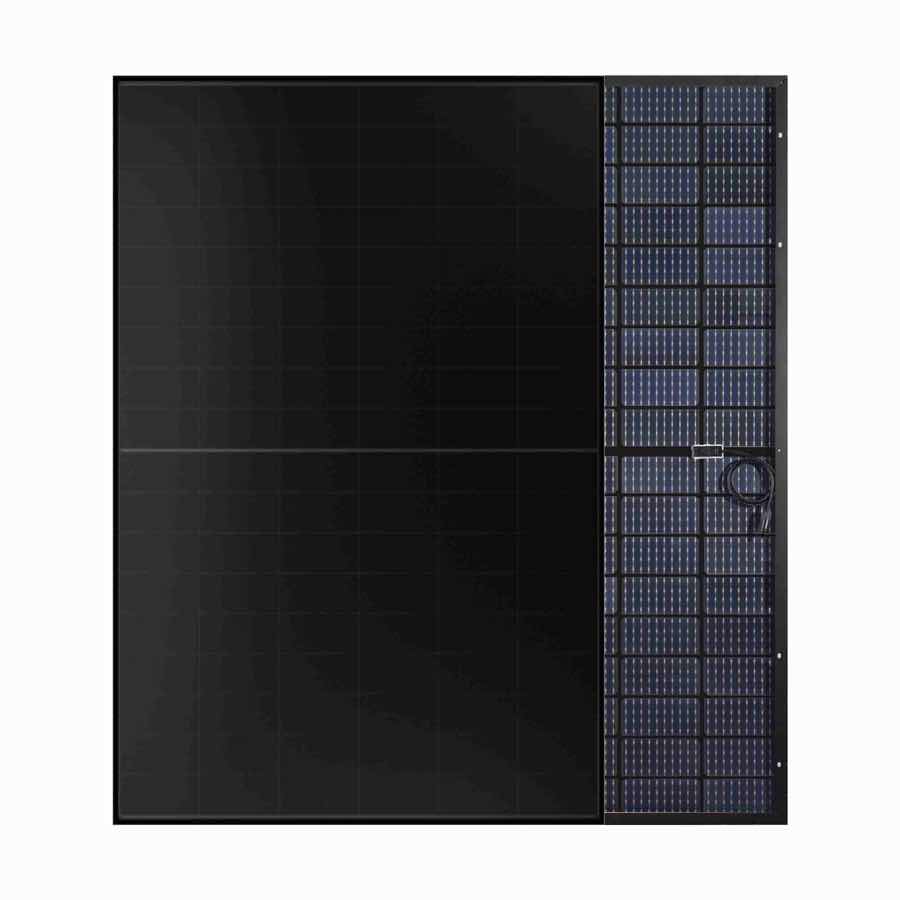

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 470/475/480/485 Watt |

| efficiency: | 23,02 - 23,76 % |

| Cells: | 108 (6*18) |

| Bifacial: | Yes, dual glass |

| Frame color: | Black |

| Front side: | 2 mm glass-glass |

| Reverse side: | black mesh |

| Dimensions: | 1800*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 470/475/480/485 Watt |

| efficiency: | 23,02 - 23,76 % |

| Cells: | 108 (6*18) |

| Bifacial: | Yes, dual glass |

| Frame color: | Black |

| Front side: | 2 mm glass-glass |

| Reverse side: | black mesh |

| Dimensions: | 1800*1134*30 mm |

| Guarantee: | 30 years |

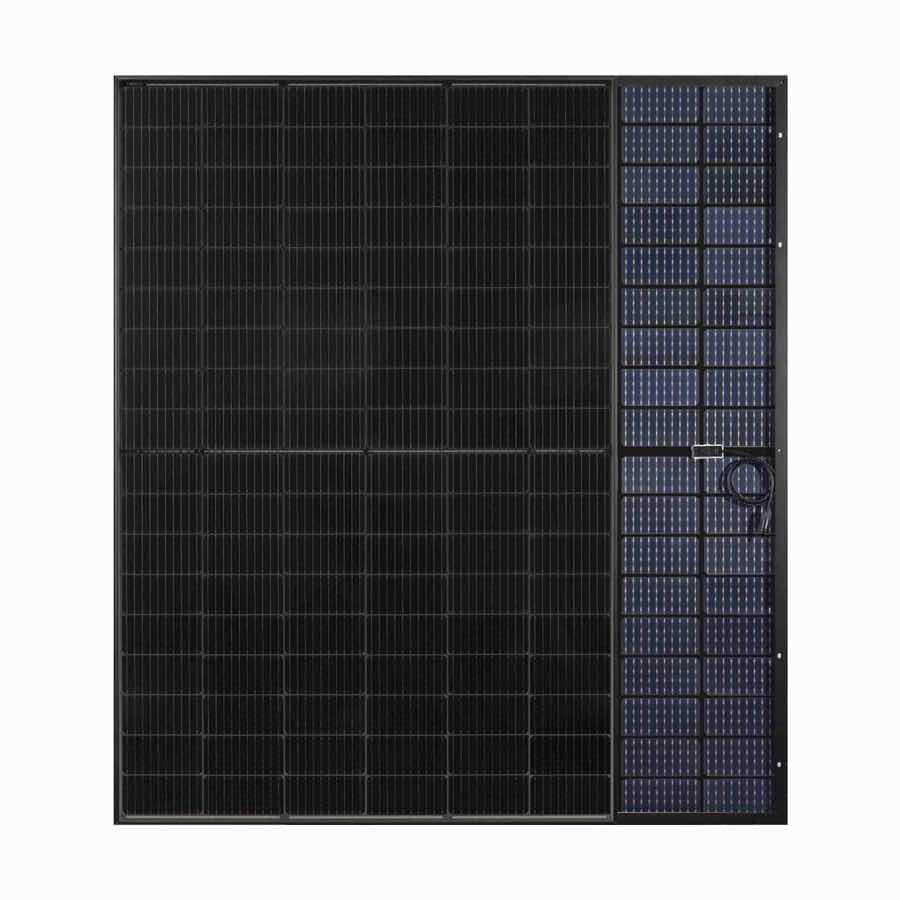

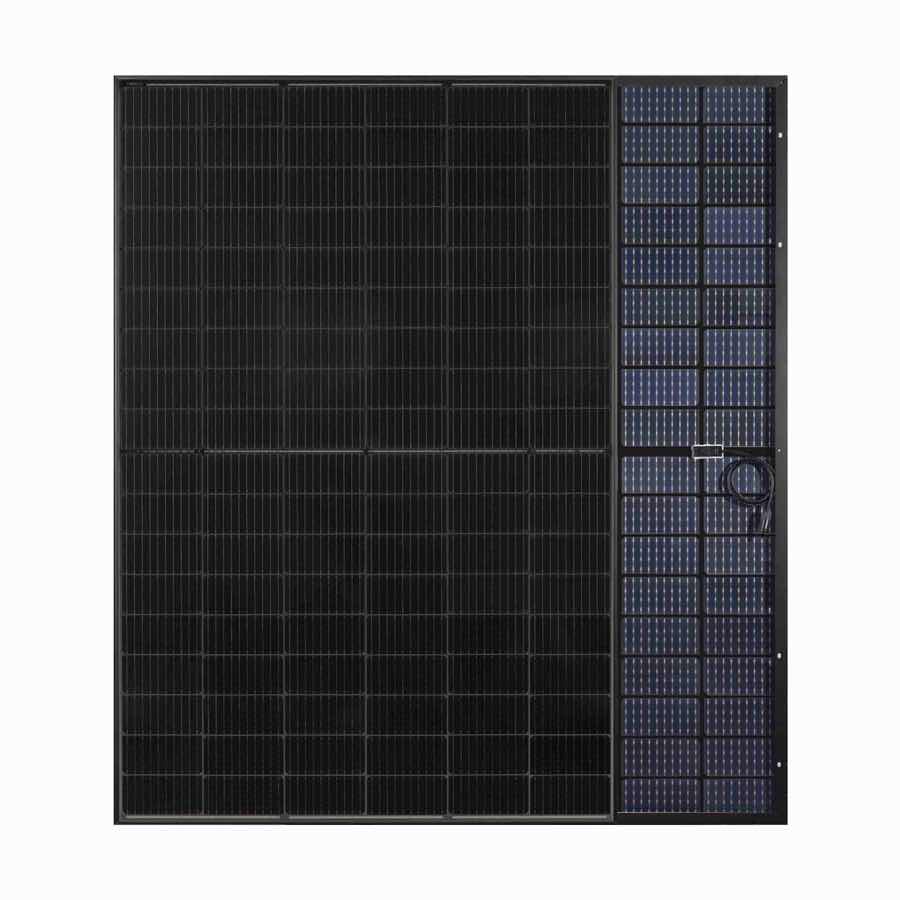

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 450/455/460/465 watts |

| efficiency: | 22,52 - 23,27 % |

| Cells: | 108 (6*18) |

| Bifacial: | Yes, dual glass |

| Frame color: | Black |

| Front side: | 2 mm glass-glass |

| Reverse side: | black mesh |

| Dimensions: | 1762*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 450/455/460/465 watts |

| efficiency: | 22,52 - 23,27 % |

| Cells: | 108 (6*18) |

| Bifacial: | Yes, dual glass |

| Frame color: | Black |

| Front side: | 2 mm glass-glass |

| Reverse side: | black mesh |

| Dimensions: | 1762*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 620/625/630/635 Watt |

| efficiency: | 22,95-23,51 % |

| Cells: | 132 (6*22) |

| Bifacial: | Yes, dual glass |

| Frame color: | silver |

| Front side: | 2 mm glass |

| Reverse side: | 2 mm glass |

| Dimensions: | 2382*1134*30 mm |

| Guarantee: | 30 years |

| Technology: | HC-Mono, N-Type, TOPCon, Nanotech Coating |

| Performance: | 620/625/630/635 Watt |

| efficiency: | 22,95-23,51 % |

| Cells: | 132 (6*22) |

| Bifacial: | Yes, dual glass |

| Frame color: | silver |

| Front side: | 2 mm glass |

| Reverse side: | 2 mm glass |

| Dimensions: | 2382*1134*30 mm |

| Guarantee: | 30 years |

| Type: | Generator connection box |

| Number of MPP trackers: | 2 |

| DC connections: | 2 |

| DC voltage: | max. 1,100 V |

| Power / input: | max. 40 A |

| Overvoltage protection: | Type T1+T2 |

| Dimensions: | 230x260x120 mm |

| IP protection class: | IP65 |

| Guarantee: | 2 years |

| Type: | Generator connection box |

| Number of MPP trackers: | 2 |

| DC connections: | 2 |

| DC voltage: | max. 1,100 V |

| Power / input: | max. 40 A |

| Overvoltage protection: | Type T1+T2 |

| Dimensions: | 230x260x120 mm |

| IP protection class: | IP65 |

| Guarantee: | 2 years |

Exclusive cooperation with Ariel RE/LLOYDS, a leading global provider of warranties for photovoltaic modules

Industry-leading warranty: Unique 30-year warranty on product and performance.

Tenka Orion technology redefines efficiency in photovoltaics. At its heart is the patented Nanotech coating, which enables an exceptionally high light yield thanks to millions of tiny prisms on the cell surface. Even weak or diffuse light is efficiently captured and converted into electricity - a clear advantage in changing weather conditions or limited light incidence.

Tenka Orion modules achieve measurably higher energy yields than conventional modules, particularly at off-peak times and when the sky is overcast. This technology maximizes the energy yield per square metre and makes roofs with limited space economically viable. At the same time, it reduces installation costs as fewer modules are required for the same output.

The combination of nanotechnology and high-quality cell architecture makes Tenka Orion an ideal solution for all areas of application - from private house roofs to large open-space systems. The optimized use of light noticeably extends the daily generation time, which creates significant additional yields, especially in the morning and evening hours.

Tenka Orion technology also impresses with long-term use: low degradation, high material quality and constant performance ensure long-term investment security. Tenka Orion modules thus set new standards for sustainable and powerful PV systems - both technically and economically.